T-Shirt Printing Machine Comparison: Reviews and Buying Guide

Choosing the right t shirt screen printing machine depends on your goals and scale. You might run a small shop or manage a large textile factory. Cnding brings over 20 years of innovation to every machine, whether you look at manual, automatic, DTG, or hybrid models. The market keeps growing, but you won’t find up-to-date sales figures for each type. For businesses prioritizing reliability and advanced technology, Cnding’s lineup offers a range of solutions designed for high performance and scalability.

Machine Types

Manual Screen Printing

Manual screen printing is the classic approach you might picture when you think about custom t-shirts. You use a frame, mesh screen, and squeegee to push ink through the stencil onto fabric. This method works best for small to medium-sized runs, especially if you want to focus on quality and unique designs. Many artists and boutique shops love manual screen printing because it lets you control every detail. You can create personalized items, single-color prints, or limited editions. If you enjoy hands-on work and value craftsmanship, this method could be a great fit. You do need some skill to get the alignment and pressure just right, but the results can be impressive.

Automatic Screen Printing

Automatic screen printing takes the manual process and adds speed and consistency. Machines handle the heavy lifting, so you can produce hundreds or even thousands of shirts in a day. If you run a busy shop or need to fill large orders, an automatic t shirt screen printing machine can save you time and effort. These machines use motors and advanced controls to move screens and apply ink with precision. You get sharp, repeatable results every time. Here’s a quick look at how production volumes compare:

| Machine Type | Production Volume (prints/hour) | Typical Use Case |

|---|---|---|

| Manual Machines | 50 – 100 | Small batches (50 – 200 prints/day) |

| Automatic Machines | 200 – 1000+ | Mass production (10,000+ T-shirts/day) |

Automatic machines can run 50–500 cycles per minute, while manual ones usually manage 5–30. If you want to scale up your business, automatic machines like those from Cnding offer the reliability and output you need.

DTG Printing

DTG, or Direct-to-Garment printing, uses inkjet technology to print designs straight onto fabric. You load your shirt, and the machine prints your image in full color, just like a desktop printer. DTG is perfect for detailed artwork, photos, or small batches where you want lots of color options. In recent years, DTG machines have seen big improvements. New pretreatment solutions make prints look better on both dark and light shirts. Print heads now handle water-based inks more smoothly, so you get fewer clogs and better results. Ink formulas have also improved, especially for white ink, which means more reliable and vibrant prints. Some companies even combine DTG with screen printing for hybrid results, giving you the best of both worlds. If you want to offer custom, colorful designs with fast turnaround, DTG could be your go-to.

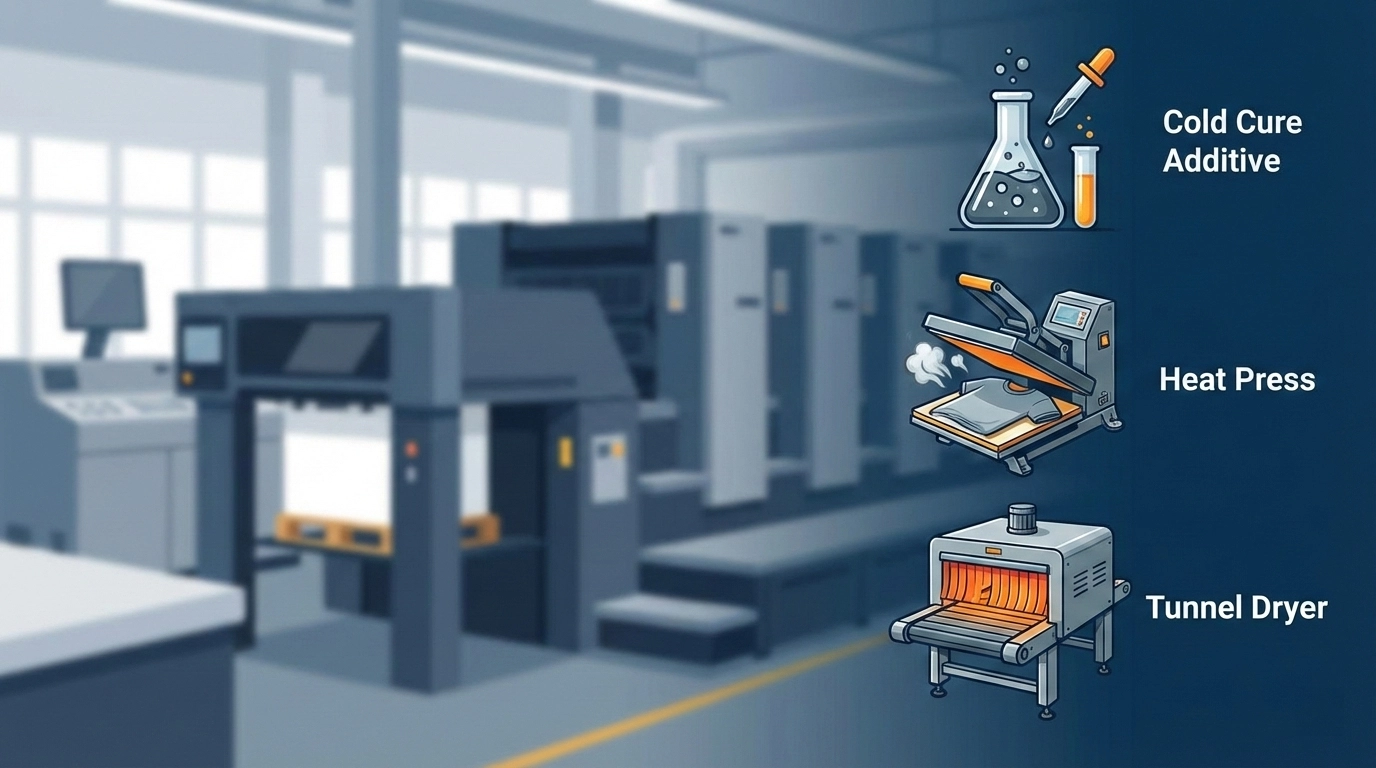

Heat Press

Heat press machines make t-shirt printing simple and fast. You use heat and pressure to transfer designs onto fabric. This method works well for custom logos, numbers, and graphics. You can create vibrant prints with just a few steps. Many small businesses and hobbyists choose heat press machines because they are easy to use and affordable.

You might wonder which fabrics work best with heat press printing. Here’s a quick table to help you decide:

| Material | Characteristics | Compatibility with Heat Press Printing |

|---|---|---|

| Cotton | Breathable, comfortable, versatile | Highly compatible, great results |

| 100% Polyester | Durable, vibrant prints | Best with dye sublimation, watch temperature |

| Cotton-Polyester Blends | Durable, comfortable, versatile | Works well with heat press |

| Tri-blend Fabrics | Soft, stretchable | Use low temperature settings |

You can print on cotton for classic tees or try blends for more stretch. Polyester works best with sublimation, but you need to watch the heat. Tri-blends need gentle care, so lower the temperature. If you want a t shirt screen printing machine that’s easy to learn, heat press is a solid choice.

Tip: Always check your fabric label before pressing. Some materials melt or scorch if the temperature is too high.

Sublimation Printing

Sublimation printing uses heat to turn dye into gas, which bonds with polyester fibers. You get bright, long-lasting prints that feel soft to the touch. This method works best on light-colored, synthetic fabrics. You can print full-color images, gradients, and even photos.

Why choose sublimation? Here are some top advantages:

- You can scale up production as your business grows.

- You get a competitive edge with high-quality, custom garments.

- You can offer a wide range of products, not just t-shirts.

- You can customize every item, making customers happy.

You also get these benefits:

- Printed areas feel soft because the dye bonds with the fabric.

- You can use unlimited colors without extra costs.

- The cost stays the same, no matter how many shirts you print.

- You don’t need plates, so you can print unique designs easily.

- Fast turnaround means you can print on demand.

- The process is environmentally friendly.

If you want to offer custom, colorful shirts with quick delivery, sublimation printing is a smart option.

Hybrid Machines

Hybrid machines combine digital and analog printing in one workflow. You get the flexibility of digital printing for short runs and custom jobs. You also get the speed and efficiency of traditional screen printing for large orders. This mix gives you more options and better results.

Here’s what hybrid machines offer:

- You can merge analog and digital technologies for versatile printing.

- You get high print quality and low costs for big orders.

- You can switch between short and long runs without changing machines.

- You can print on many types of fabric and products.

- You get speed, precision, and full customization.

Cnding’s hybrid t shirt screen printing machine solutions let you handle both creative and bulk jobs. You can print detailed designs for small batches or crank out thousands of shirts for big events. Hybrid machines help you stay competitive and meet every customer’s needs.

t shirt screen printing machine Comparison

Pros and Cons

When you look at different t shirt screen printing machine types, you’ll notice each one has its own strengths and weaknesses. If you want a quick overview, check out this table:

| Printing Method | Pros | Cons |

|---|---|---|

| Manual Screen Printing | Great for small batches, hands-on control, affordable setup | Slow for big orders, needs skill, limited detail |

| Automatic Screen Printing (Cnding H9PRO, NB Plus, H8) | Fast production, high precision, consistent results, scalable for growth | Higher initial investment, needs space |

| Direct to Garment (DTG) | Quick for small runs, full-color designs, eco-friendly inks | Needs pre-treatment, less vibrant on dark shirts, not for all fabrics |

| Heat Transfer Printing | Easy to use, flexible designs, good for small batches | Less durable, rubbery feel, slow for large orders |

| Sublimation Printing | Soft prints, unlimited colors, vibrant results, no fading | Only works on polyester, not for dark shirts, higher startup cost |

| Hybrid Machines (Cnding Hybrid Solutions) | Combines speed and flexibility, handles complex jobs, versatile | Higher investment, more complex setup |

If you run a busy shop or want to scale up, automatic machines like Cnding’s H9PRO Series, NB Plus, and H8 stand out for speed and reliability. You get consistent quality and can handle big orders with ease.

Tip: Think about your business size and the types of jobs you want to take on. The right machine can save you time and money.

Print Quality

You want your prints to look sharp and last long. Print quality depends on the machine type and the method you choose. Here’s how the main options stack up:

| Printing Method | Color Vibrancy | Detail Accuracy | Best Use Case |

|---|---|---|---|

| Manual Screen Printing | Very High | Good | Simple designs, small batches |

| Automatic Screen Printing (Cnding H9PRO, NB Plus, H8) | Very High | Excellent | Large orders, multi-color prints |

| DTG Printing | High | Excellent | Photos, complex artwork |

| Heat Transfer Printing | Good | Good | Custom logos, small runs |

| Sublimation Printing | Vibrant | Good | Sportswear, all-over prints |

| Hybrid Machines (Cnding Hybrid Solutions) | Very High | Excellent | Custom and bulk jobs |

Automatic t shirt screen printing machine models from Cnding deliver top-notch print quality. You get vibrant colors and crisp details, even on large runs. Sublimation gives you soft, colorful prints that don’t crack or fade, but you need polyester fabric. DTG works best for detailed images and photos.

Note: If you want prints that last through many washes, screen printing and sublimation are your best bets.

Cost

Cost is a big factor when you choose a t shirt screen printing machine. You need to think about both the upfront price and ongoing expenses.

- Manual machines cost less to start. You can get going for a few hundred to a few thousand dollars.

- Automatic machines, like Cnding’s H9PRO Series, NB Plus, and H8, require a bigger investment. Prices range from $10,000 to $100,000, but you get much higher output and lower labor costs.

- DTG printers sit in the middle. You pay more than manual but less than industrial automatic machines.

- Heat transfer and vinyl cutting machines are affordable for small shops. Maintenance is simple, but prints may not last as long.

- Sublimation machines cost more upfront. You also need special inks and polyester garments, which adds to your budget.

Ongoing costs include ink, screens, maintenance, and energy. Automatic machines from Cnding help you save on labor and reduce waste, which can lower your total cost over time.

If you plan to grow your business or handle big orders, investing in a high-quality automatic t shirt screen printing machine pays off in the long run.

Durability

When you invest in a t shirt screen printing machine, you want it to last. Durability matters because it affects your long-term costs and how often you need repairs. Let’s look at how different machines stack up.

Automatic screen printing machines, like Cnding’s H9PRO Series, NB Plus, and H8, use solid construction and advanced engineering. These machines feature military-grade aluminum-magnesium alloy platforms and servo motors. You get a machine that resists wear and tear, even with heavy use. Many businesses run these machines 24/7 without issues. You can expect years of reliable service.

Manual screen printing machines offer decent durability for small shops. If you take care of them, they last a long time. However, they may need more frequent maintenance if you ramp up production.

DTG printers and heat press machines have moving parts and electronics. You need to keep them clean and follow maintenance schedules. Sublimation printers work well for polyester fabrics and usually hold up over time, but you must use the right inks and materials.

Hybrid machines combine the best features of digital and analog printing. Cnding’s hybrid solutions use robust materials and smart design. You get a machine that stands up to high-volume jobs and frequent changeovers.

Tip: Always follow the manufacturer’s maintenance guide. Regular cleaning and inspections help your machine last longer.

Ease of Use

You want a t shirt screen printing machine that’s easy to operate. If you’re new to printing or training staff, user-friendly controls make a big difference.

Manual screen printing requires skill and practice. You need to learn how to align screens, apply ink, and control pressure. Once you master the basics, you can create beautiful prints. However, it takes time to get consistent results.

Automatic machines, like Cnding’s H9PRO Series, NB Plus, and H8, come with touchscreen interfaces and smart controls. You can set up jobs quickly and monitor progress in real time. These machines offer remote support and troubleshooting, so you spend less time fixing problems. You don’t need advanced technical skills to run them. Training is straightforward, and you can get started fast.

DTG printers work like desktop inkjet printers. You load your shirt, select your design, and hit print. The process is simple, but you need to pretreat garments and maintain the print heads.

Heat press machines are easy to learn. You set the temperature, place your design, and press. Most people pick up the basics in a day.

Sublimation printers need some setup, but the process is smooth once you understand the steps. Hybrid machines from Cnding combine digital and analog workflows. You get intuitive controls and flexible options for different jobs.

Note: If you want to save time and reduce training costs, choose a machine with a user-friendly interface and clear instructions.

Best Use Cases

Choosing the right t shirt screen printing machine depends on your business size and the types of jobs you handle. Here’s a quick guide to help you decide:

| Printing Method | Best Use Cases | Business Size |

|---|---|---|

| DTG Printing | Ideal for on-demand, customized orders and businesses specializing in detailed artwork and short runs. | Small to Medium |

| Sublimation | Eye-catching designs on polyester t-shirts. Custom sportswear, team uniforms, and promotional items. | Medium to Large |

| Screen Printing | Best for high-volume, repeat orders and businesses focused on wholesale or large-scale retail. | Large |

You might find DTG printing perfect if you run a boutique shop or want to offer custom artwork. Sublimation works best for sportswear and promotional items, especially on polyester. Screen printing shines when you need to produce thousands of shirts for events or retail.

Let’s break it down further:

- DTG Printing: Great for small batches, custom orders, and detailed graphics.

- Sublimation: Ideal for polyester garments, sports teams, and vibrant promotional gear.

- Screen Printing: Best for bulk orders, uniform designs, and high-speed production.

Cnding’s automatic and hybrid machines help you scale up quickly. You can handle large orders, maintain quality, and expand your product range. If you want to grow your business, these machines give you the flexibility and reliability you need.

If you’re planning to expand or take on bigger clients, consider a machine that matches your production goals.

Machine Reviews

Cnding H9PRO Series Full-Servo Oval Printing Machine

Features

You get a machine built for precision and speed. The H9PRO Series uses full-servo control technology, which means every print comes out sharp and consistent. You can choose from 6 to 24 color stations, so you have flexibility for any job size. The touchscreen interface makes setup easy. You can monitor progress and troubleshoot without hassle. The solid aluminum pallets keep your prints stable, and the dual servo motor system gives you 360° control over every detail. Energy efficiency is a big plus. The H9PRO cuts power costs by up to 30%.

Advantages

You boost your productivity with this machine. The H9PRO prints up to 700 pieces per hour in 16-color mode. You save on labor because the automation handles most tasks. The machine’s patented technology ensures flawless registration, so you don’t waste shirts on misprints. Maintenance is simple, thanks to the concealed servo motors and easy-access design. You also get a 12-month warranty and responsive tech support. Many textile companies trust this model for its reliability and high output.

Real-world impact: Businesses utilizing the H9PRO series commonly report measurable improvements in color consistency and a corresponding increase in customer satisfaction scores. They reduced production errors and improved efficiency, which helped them stay ahead in the market.

Ideal Users

You should consider the H9PRO Series if you run a large textile factory or a busy print shop. This machine fits businesses that need high-volume, multi-color printing with minimal downtime. If you want to scale up your operations and deliver top-quality prints, the H9PRO is a smart investment.

Cnding NB Plus Oval Screen Printer Machine

Features

You get precision printing with ±0.01mm accuracy. The NB Plus uses a stable servo drive system, so every shirt looks perfect. You can expand the machine from 6 to 24 color stations, which means you can grow your business without buying a new machine. The quick-release system lets you change plates in just 90 seconds. You can print on t-shirts, towels, and other garments. The NB Plus supports 12 specialized printing techniques, including water-based and solvent-based inks. The intelligent temperature-controlled stamping system adapts to different fabrics, so you get reliable results every time.

- Precision printing with ±0.01mm accuracy

- Powered by a stable servo drive system

- Ideal for high-volume screen print production

- Supports smooth operation and reduced downtime

- Highly reliable for the garment industry

- Suitable for printing t-shirts and towels

Advantages

You enjoy ultra-high registration accuracy, which means sharp and detailed prints. The NB Plus is versatile. You can handle delicate silk or heavy denim with ease. The modular design lets you add more stations as your business grows. You save energy and reduce costs with its efficient motors. The preventive maintenance system gives you alerts before problems happen, so you avoid unexpected downtime. You get a machine that runs smoothly and keeps your shop productive.

Textile companies in Bangladesh use the NB Plus to meet large orders and tight deadlines. They report better color vibrancy and fewer production errors, which helps them compete in the global market.

Ideal Users

You should choose the NB Plus if you manage a medium to large print shop or textile business. This machine is perfect for companies that want to expand their product range and handle complex printing jobs. If you need reliability and flexibility, the NB Plus delivers.

Cnding H8 Frequency Conversion Silk Printing Machine

Features

You get a machine designed for industrial-scale printing. The H8 uses a split design, which separates screen frame movement from squeegee operation. This keeps colors aligned and prints consistent. You can print on ceramics, glass, metal, and PCBs, not just fabric. The military-grade aluminum-magnesium alloy pallet platform resists deformation, so your prints stay flat. The frequency conversion drive cuts energy use by 30%. You can expand the machine from 6 to 24 color stations, so it grows with your business.

| Feature | Details |

|---|---|

| Steady Printing | Vertical lifting frame for precise alignment. |

| Ink Versatility | Compatible with water-based, solvent-based, fluorescent, and UV inks. |

| Low Noise | Servo motor drive for quiet operation in small spaces. |

| Modular Design | Add workstations to boost output. |

| Built to Last | Sturdy steel frame for long-term reliability. |

| Output (16 colors) | 600 pieces/hour. |

Advantages

You get consistent print quality, even on tough materials. The H8’s split design prevents color misalignment, so you avoid costly mistakes. The machine runs quietly, which is great if you have limited space. You save on energy bills with its efficient drive system. The sturdy frame means you won’t worry about breakdowns. You can handle high-volume orders and switch between different substrates without slowing down.

Textile companies in Bangladesh rely on the H8 for large orders. They see fewer misprints and faster turnaround times, which helps them grow their business.

Ideal Users

You should pick the H8 if you run an industrial printing operation or need to print on a variety of materials. This machine suits businesses that demand high output and precision. If you want a t shirt screen printing machine that can handle tough jobs and keep running day and night, the H8 is a top choice.

Other Machine Types

Features

You have a lot of choices when it comes to t shirt printing. Each machine type brings something different to the table. Here’s a quick look at what you can expect:

- Manual Screen Printing Machines You control every step. You use a frame, mesh screen, and squeegee. You get hands-on experience and can create unique designs. These machines work well for small batches and simple prints.

- DTG (Direct-to-Garment) Printers You print full-color images right onto the shirt. You load your design into the printer, and it does the rest. DTG works best for detailed artwork and small orders.

- Heat Press Machines You use heat and pressure to transfer designs onto fabric. You can work with vinyl, transfer paper, or sublimation sheets. These machines are easy to use and great for beginners.

- Sublimation Printers You use special inks and polyester shirts. The ink turns into gas and bonds with the fabric. You get bright, long-lasting prints that feel soft.

- Hybrid Machines You combine digital and screen printing in one workflow. You can switch between short custom runs and big bulk orders. These machines give you flexibility and speed.

Note: Each machine type has its own learning curve. You might need to try a few before you find the best fit for your business.

Pros and Cons

Let’s break down the main advantages and disadvantages of each machine type. This table will help you compare at a glance:

| Machine Type | Pros | Cons |

|---|---|---|

| Manual Screen Printing | Affordable, hands-on, great for small runs | Slow, needs skill, not ideal for big orders |

| DTG Printing | Full-color, detailed prints, easy setup | Slower for bulk, higher ink costs |

| Heat Press | Simple to use, low cost, quick for small jobs | Prints may crack or peel, not for all fabrics |

| Sublimation | Soft, vibrant prints, no fading | Only works on polyester, higher startup cost |

| Hybrid Machines | Flexible, handles complex jobs, scalable | More expensive, complex setup |

Tip: Think about your main customers. Do they want custom one-offs or big batches? Your answer will help you pick the right machine.

Best For

You want a t shirt screen printing machine that matches your business goals. Here’s a quick guide to help you decide:

- Manual Screen Printing: Best for artists, hobbyists, and small shops. You get creative control and can make unique designs.

- DTG Printing: Perfect for custom orders, photo prints, and small businesses that want to offer lots of color options.

- Heat Press: Great for beginners, sports teams, and anyone who needs fast, simple prints.

- Sublimation: Ideal for sportswear brands, promotional companies, and anyone working with polyester garments.

- Hybrid Machines: Best for growing businesses that want to handle both custom and bulk orders without switching equipment.

If you’re just starting out, try a manual or heat press machine. If you want to scale up, look at hybrid or automatic options.

Buying Guide

Business Size

You want a machine that matches your business size. If you run a small shop or just started, you might not need a huge setup. For beginners, heat press machines work well. They are easy to use and don’t take up much space. Direct-to-garment (DTG) printers also fit small businesses, especially if you focus on custom designs or short runs.

If your business is growing, you may need more speed and flexibility. Direct-to-film (DTF) printers offer detailed designs and work with many fabrics. They cost less than DTG but give you more options.

For large companies or factories, screen printing machines are the top choice. They handle big orders, print fast, and keep costs low for bulk jobs. You need more space, but you get high-quality, durable prints.

Here’s a quick table to help you decide:

| Machine Type | Best Suited For | Key Features |

|---|---|---|

| Screen Printing Machines | Large batch production | High-quality prints, cost-effective for bulk orders, vibrant colors, durable prints. Requires significant setup space. |

| Heat Press Machines | Small businesses, beginners | User-friendly, affordable ($79 to $399), ideal for quick applications of pre-made designs. Lower quality compared to others. |

| Direct-to-Garment (DTG) | Small batch, custom designs | Excellent print quality, quick turnarounds, intricate designs. Higher initial costs (around $1,000). Requires fabric pre-treatment. |

| Direct-to-Film (DTF) | Versatile small businesses | Combines benefits of DTG and heat transfer, detailed designs, fabric compatibility. More affordable than DTG ($3,000 to $9,000). |

Tip: Think about how many shirts you print each week. If you plan to grow, choose a machine that can scale with your business.

Fabric Compatibility

You want your t shirt screen printing machine to work with the fabrics you use most. Some machines print only on cotton, while others handle polyester, blends, or even specialty materials.

If you plan to offer many types of shirts, sportswear, or custom items, pick a machine that supports multiple fabrics. This gives you more flexibility and helps you meet customer needs.

Design Needs

You want your t-shirt prints to stand out. Maybe you need bold colors, sharp details, or fast turnaround for big orders. Your design needs shape the kind of t shirt screen printing machine you should buy. If you plan to print complex artwork or lots of colors, look for machines with advanced color capabilities and high print resolution. If you handle bulk orders, speed and reliability matter most.

Let’s break down what to check before you decide:

| Feature | What to Look For |

|---|---|

| Technical Specifications | High print resolution, fast print speed, large platen sizes, support for many garment types, and good connectivity. |

| Performance Metrics | Real-world throughput, low ink consumption, easy maintenance, and long-lasting parts. |

| Cost-Efficiency Factors | Total cost of ownership, including purchase price, ink, maintenance, and consumables. |

| Quality Assurance | Machines that deliver vibrant, durable prints with consistent color reproduction. |

| Integration Capabilities | Compatibility with your design software and ability to connect with online stores or management systems. |

If you run a creative shop, you might want a machine that handles intricate graphics and lots of colors. For high-volume businesses, speed and cost-efficiency are key. Cnding’s automatic and hybrid machines offer flexible color setups, high-speed production, and easy integration with design tools. You can scale up as your business grows and keep your prints looking sharp.

Tip: Make a list of your top design needs. Match those with machine features before you buy. This helps you avoid costly mistakes and keeps your customers happy.

Vendor Selection

Choosing the right vendor is just as important as picking the right machine. You want a partner who supports you long after the sale. Reliable vendors help you avoid downtime and keep your business running smoothly.

Here’s what to look for:

- Check if the vendor offers a steady supply of spare parts.

- Ask about technician response times for repairs.

- Review warranty coverage—look for at least one year.

- Find out how long the supplier has been in business. More than 10 years means better support.

- Investigate their reputation for technical support and training.

- See if they have local service networks to help you quickly.

| Criteria | Why It Matters |

|---|---|

| Spare Parts Availability | Quick access to parts keeps your machine running. |

| Technician Response Time | Fast service means less downtime and fewer missed deadlines. |

| Warranty Coverage | A solid warranty protects your investment. |

| Supplier Experience | Experienced vendors offer better advice and technical help. |

Cnding stands out with over 20 years of experience, strong after-sales support, and a global network. You get responsive service, comprehensive training, and reliable warranty coverage. When you choose a vendor, think about long-term support, not just the initial purchase.

Note: Ask for references or customer stories. Real feedback helps you see how vendors handle problems and support their clients.

You want the best t-shirt screen printing machine for your business. Think about printing width, daily output, ease of use, budget, fabric compatibility, warranty, and customer support. If you run a large shop or need high-volume, multi-color prints, Cnding’s automatic and hybrid machines give you speed and reliability. For small batches or custom jobs, manual or DTG options work well. Explore Cnding’s lineup to find a solution that fits your goals. Reach out for personalized advice and get the support you deserve.

FAQ

What’s the best t-shirt printing machine for beginners?

If you’re just starting out, try a manual screen printing or heat press machine. You’ll find them easy to use and affordable. You can learn the basics fast and upgrade later when your business grows.

How do I choose the right machine for my business size?

Check your daily order volume. Small shops do well with manual or DTG machines. Large businesses need automatic or hybrid machines like Cnding’s H9PRO Series for speed and reliability.

Can I print on different fabrics with one machine?

You can print on cotton, polyester, blends, and more. Automatic machines from Cnding handle many fabric types. Always check the machine specs before you buy.

How much maintenance does a screen printing machine need?

You should clean screens, check ink levels, and inspect moving parts regularly. Cnding machines come with smart alerts and easy-access designs, so you spend less time on upkeep.

What’s the average lifespan of a t-shirt printing machine?

Most machines last 5–10 years with proper care. Cnding’s models use durable materials and advanced engineering, so you get reliable performance for years.

Do I need special training to use an automatic machine?

You don’t need advanced skills. Cnding’s automatic machines feature touchscreen controls and guided setup. You can learn quickly with their training and support.

How do I get support if my machine breaks down?

You can contact Cnding’s global support team by email or phone. They offer fast response times, spare parts, and remote troubleshooting to keep your business running.

Tip: Always keep your warranty info handy for quick service.

- Machine Types

- t shirt screen printing machine Comparison

- Machine Reviews

- Buying Guide

-

FAQ

- What’s the best t-shirt printing machine for beginners?

- How do I choose the right machine for my business size?

- Can I print on different fabrics with one machine?

- How much maintenance does a screen printing machine need?

- What’s the average lifespan of a t-shirt printing machine?

- Do I need special training to use an automatic machine?

- How do I get support if my machine breaks down?