How to Start a Profitable Screen Printing Business in 2026

You can make a screen printing business that earns money in 2026 if you set clear goals, use smart plans, and get the best equipment. The industry is growing because more people want custom things and companies need better solutions.

- The North America industrial screen printing market will be worth $7.08 billion by 2033, and it will grow by 5.1% each year.

- You will do well if you make your work simple, control spending, use new technology, and give more services. If you buy automation and trusted machines like those from Cnding, you will get good results and keep growing.

Screen Printing Business Opportunity

Market Demand

In 2026, many people will want screen printing services. Different industries need custom prints for their products. The market keeps getting bigger every year.

- The North America custom screen printing market will go from $5.5 billion in 2024 to $9.2 billion by 2033. This means it will grow by 6.5% each year.

- The North America silk screen printing services market will grow from $4.5 billion in 2024 to $6.8 billion by 2033. This is a 5.0% growth rate each year.

Many types of businesses need screen printing. The table below shows how different industries use it:

| Industry/Sector | Application of Screen Printing |

|---|---|

| Consumer Electronics | Decorative panels, printed circuitry, touchscreens |

| Automotive | Dashboard panels, indicator lighting, durable graphics |

| Apparel | Custom clothing, creative designs, vibrant inks |

| Packaging | Labeling, branding, durable packaging |

| Promotional Items | High-quality promotional materials |

| Industrial Manufacturing | Safety signs, instructions, durable surfaces |

Key Advantages

Starting a screen printing business gives you many good things.

- You can save money on big orders because you can use screens again. This makes each item cost less.

- The prints last a long time. They stay bright and strong after many washes.

- You can use special inks to make bright and bold designs.

- You can give each customer a special design. This gives them more choices.

- You can print on lots of things, like shirts and signs.

Tip: These benefits help you get more customers and keep them happy.

Startup Costs

You can begin a screen printing business with different amounts of money. The main things you pay for are equipment, supplies, and a place to work.

- Manual setups cost less but need more work from you.

- Automatic machines, like the ones from Cnding, cost more at first. But they save time and help you make fewer mistakes.

- You also need to buy inks, screens, and cleaning supplies.

- Renting a small place to work and paying for utilities will add to your costs.

Make a careful plan for your budget. Pick equipment that fits your goals and the size of orders you expect.

Business Model & Clients

Define Goals

You should set goals before you start your business. Goals help you focus and see how you are doing. Many owners pick three to five main goals. These goals help them make good choices. Goals can be about different parts of your business. The table below shows some common goals:

| Goal Type | Description |

|---|---|

| Overarching Goals | Pick three to five big goals for your business |

| Customer Satisfaction | Make sure customers like your service |

| Consistent Quality | Keep your products good every time |

| Operational Efficiency | Make your work faster and easier |

| Brand Recognition | Help more people know your brand |

| Team Development | Build a strong and skilled team |

| Sustainability | Run your shop in a way that helps the planet |

Tip: Write your goals down and look at them often. This helps you stay focused and grow.

Target Customers

You need to know who your best customers are. Good clients help your business do well. They have clear needs and talk with you easily. They care about quality and fair prices. The table below shows what good customers are like:

| Characteristic | Description |

|---|---|

| Understanding specific needs | They know what they want and tell you |

| Communication styles | They talk clearly and answer fast |

| Project requirements | They have fair ideas about cost and time |

| Industry segments | They work in areas that fit your skills |

| Purchase frequency | They buy from you often, not just once |

| Budget and project scope | They want good quality, not just the lowest price |

Note: Focus on these customers to make selling and marketing easier.

Customer Solutions

You can give better help when you know your customers well. Many screen printing shops only take orders that match their skills and make money. They set prices and watch costs. You should:

- Give custom designs to each client

- Use good materials for strong prints

- Talk clearly about time and cost

- Pick the best printing method for each job

When you help your best customers and give great service, you get a good name and steady money.

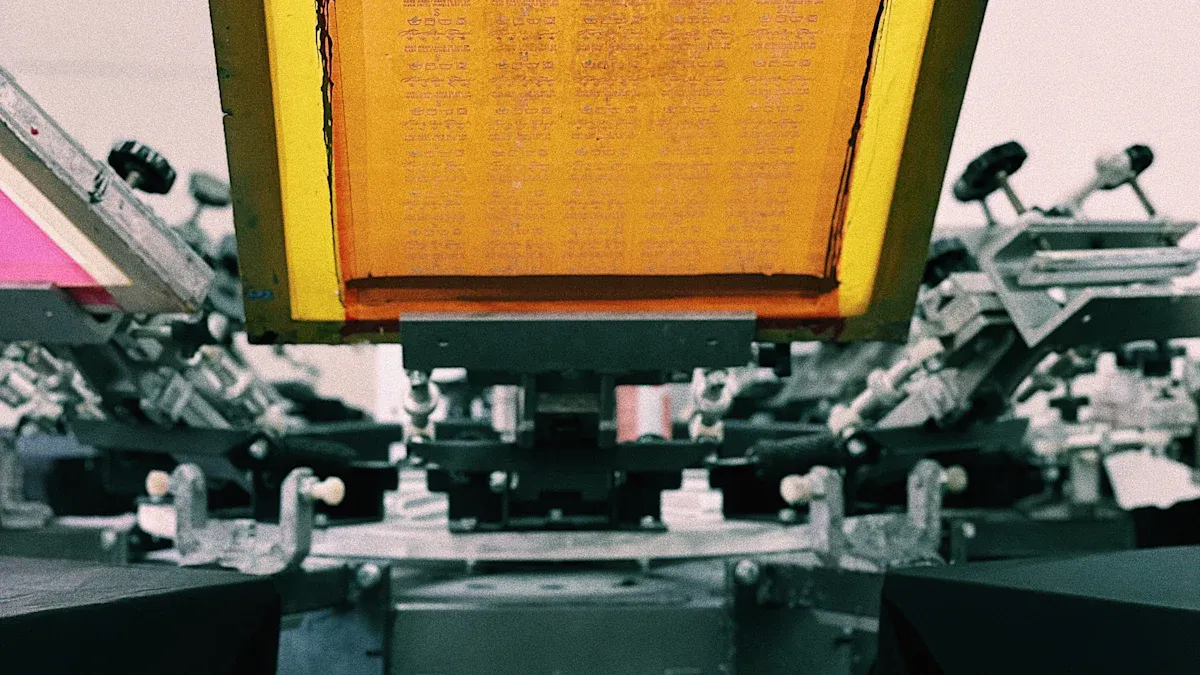

Equipment & Setup

Manual vs. Automatic

You must pick between manual or automatic presses. Manual presses are slower and cost more to use. Two people with manual presses can print 120 shirts in one hour. Two people with automatic presses can print 500 shirts in the same time. Automation lowers labor costs to 24%. If you print 1,000 shirts with one color, a manual press takes 10 hours. An automatic press only needs 2.5 hours. Automatic presses save time and money for big jobs.

Solutions

Cnding makes machines that help you work faster and better. The NB Plus Oval Screen Printer Machine gives sharp prints with ±0.01mm accuracy. It works with many printing techniques. The H8 Frequency Conversion Silk Printing Machine uses full-servo control. This gives steady quality and saves energy. The Oval Screen Printing Machine For Shoes is great for shoe uppers. It handles hard designs easily. These machines are precise, quick, flexible, and save energy. You can pick models with up to 24 color stations.

Tip: Cnding’s machines help your business grow and keep costs down.

Setup Tips

You need the right tools to begin. Here is a table of what you need:

| Equipment Type | Description |

|---|---|

| Mesh Screens | Used for creating stencils for printing. |

| Racks for Printing | Hold items during the printing process. |

| Racks for Drying | Dry printed items safely. |

| Special Fabric Inks | Achieve quality prints on fabric. |

Set up your workspace to be safe and fast. Keep your area neat and avoid mess. Make zones for each job, like printing and drying. Keep your design area clean and dust-free. Make sure you have good airflow to avoid bad fumes. Take care of your equipment and clean up often. Throw away waste the right way to help the environment. Check your studio layout to find and fix slow spots.

Note: A tidy shop helps you work faster and keeps everyone safe.

Launch Steps

Design Prep

You need to prepare your designs carefully before you start printing. Good design prep helps you get sharp and clear prints every time. Follow these steps to set up your artwork:

- Choose the right file format. Use vector files like AI or EPS for logos and illustrations. For photos, pick high-resolution PSD or TIFF files.

- Organize your design layers. Put each color on its own layer and add registration marks outside the design area.

- Separate the colors. Make sure each color stands alone and leave enough space between design elements.

- Check your resolution and design specs. Use at least 300 DPI, keep line thickness above 0.5 points, and text size above 6 points.

- Review and export your file. Convert text to outlines and make sure registration marks are visible.

Tip: Proper design prep is the foundation of every successful print job.

Printing Process

You can start printing once your design is ready. The process has several important steps:

- Place your item on the printing pallet and secure it to avoid movement.

- Pre-treat the material if needed for better ink adhesion.

- Set up your screen with the correct mesh count for your design.

- Mix your ink to the right thickness. Thick ink prevents bleeding and keeps lines sharp.

- Use a squeegee to pull ink across the screen. Keep your pressure and angle steady for even coverage.

- Lift the screen and check the print for smudges or misalignment.

- Dry or cure the print at the right temperature and time.

Note: Regularly check your screens for tension and clean them to avoid problems.

Quality Tips

You want every print to look great and last long. Use these quality control tips to keep your work consistent:

- Keep your print strokes the same for each item.

- Watch the drying and curing times to make sure ink sticks well.

- Check prints during production for color, alignment, and defects.

- Test your prints for durability by washing or rubbing them.

- Maintain your equipment and calibrate it often.

- Train your team so everyone knows the right steps.

A strong focus on quality helps your screen printing business build a good reputation and keeps customers coming back.

Optimize Operations

80/20 Rule

You can make your business more profitable by using the 80/20 rule. This rule says that 80% of your results come from 20% of your efforts. In a screen printing business, you should focus on the customers, products, and processes that bring in the most profit. Here is how you can use the 80/20 rule:

| Strategy | Description |

|---|---|

| Focus on Top Customers | Pay special attention to your best customers. They often bring repeat orders and steady income. |

| Optimize Products | Find out which products make the most money. Promote these and think about stopping low-profit items. |

| Streamline Operations | Improve the steps that give you the most results. This saves time and resources. |

| Implement Pricing Strategy | Adjust prices for your top products and customers to earn more without working harder. |

| Nurture Remaining Customers | Keep in touch with all customers. Some may grow and become top clients in the future. |

Tip: Review your sales and production data every month. This helps you spot your top 20% and make smart choices.

Automation

Automation helps you work faster and with fewer mistakes. When you use advanced machines and tools, you can print more items in less time. Cnding’s equipment, like the NB Plus Oval Screen Printer Machine and the H8 Frequency Conversion Silk Printing Machine, uses smart servo systems for high accuracy and speed. These machines can handle many colors and designs, making your shop more flexible.

You can also use other automation tools to improve your workflow:

| Automation Tool | Description |

|---|---|

| Auto Coater | Applies screen coating evenly every time, so your prints look sharp and clear. |

| Laser-To-Screen Units | Uses lasers to make screens quickly and accurately, skipping old slow methods. |

| Squeegee Cleaning System | Cleans your tools automatically, saving you time and keeping tools ready for the next job. |

| Drum Dispensing Unit | Mixes chemicals and inks with the right amounts, cutting waste and making work easier. |

- Robotic printing presses can handle big orders and many designs without slowing down.

- Automatic screen-coating machines keep your emulsion layers even, which means less waste and better prints.

Note: Automation lets you take on bigger jobs, reduce errors, and keep your team focused on important tasks.

Workflow

A smooth workflow helps you finish jobs faster and keeps customers happy. You can use these steps to make your shop run better:

- Use artwork approval software. Customers can check and approve designs online, which saves time and avoids mistakes.

- Check your workflow often. Look for slow spots and fix them to keep things moving.

- Take care of your equipment. Clean and maintain your machines so they work well every day.

- Make screen preparation simple. Set up a clear process for getting screens ready to print.

- Plan your jobs with scheduling tools. Group similar jobs together to save setup time.

- Write down standard steps for each task. These instructions help new workers learn quickly and keep quality high.

- Use good communication tools. Make sure everyone knows what jobs are coming up and what needs to be done.

- Train your team often. Teach them new skills and how to use new machines.

- Give customers clear rules for artwork. This helps avoid delays and makes printing easier.

A well-organized workflow means you can handle more orders, keep quality high, and grow your business with less stress.

Pricing & Costs

Pricing Strategy

You need a good plan for setting prices. First, look at what other shops charge. This helps you know what is normal. Next, figure out all your costs. Add some extra money so you make a profit. This way, you do not lose money on orders. You can also set prices by thinking about what your product is worth to customers. Some people will pay more for special designs or quick work. Try using prices like $19.99 instead of $20.00. This makes things look cheaper to buyers.

- Check what other shops charge for their work.

- Add up your costs and include a fair profit.

- Think about how much your product helps the customer.

- Use prices that end in .99 to attract buyers.

It is important to know your contribution margin. This shows how much money you keep after paying for materials and labor. It helps you pay for things like rent and make a profit.

Cost Control

You need to watch your costs to keep your business safe. The biggest costs are materials, worker pay, and shipping. Using machines can help you save on worker pay and make fewer mistakes. Check your prices and how you work often to stay ahead.

| Cost Driver | Description |

|---|---|

| Material Costs | Inks, screens, and garments |

| Labor Costs | Wages for printing staff |

| Fulfillment Fees | Shipping and handling expenses |

| Damaged Goods | Losses from defective products |

| Automation Tools | Technology that boosts efficiency |

| Regular Evaluation | Ongoing review of pricing and workflow |

- Use machines to lower worker pay.

- Check your prices and work steps often.

Common Pitfalls

Many new shops have trouble with cash flow. You must know how much money comes in and goes out. This helps you see if you can take new jobs. Some owners say yes to too many jobs. Be honest about how much you can make to keep customers happy.

- Do not promise more than you can do.

- Watch your money so you can pay for new jobs.

- Always check your money before taking big orders.

Knowing your costs and limits helps you avoid mistakes and keeps your business strong.

Scale Your Screen Printing Business

Growth Tactics

You can make your screen printing business bigger with smart steps. Many shops buy new machines to work faster and better. Cnding’s machines, like the NB Plus Oval Screen Printer, let you add more colors as you get more orders. You should also make your supply chain better to save money and deliver faster. Good customer service keeps your clients happy as your shop grows.

Here are some ways to grow:

- Use eco-friendly steps to get customers who care about the earth.

- Work with local artists to find new buyers and make cool designs.

- Learn about new trends so you can offer new styles.

- Train your team to help them get better and keep your products good.

Tip: Growing works best when you use new machines, give good service, and work with others.

Automation & Training

Automation lets you fill more orders with less work. Cnding’s machines use servo systems for fast and exact printing. You can print more things in less time and make fewer mistakes. But machines are not enough. You need a trained team to use new machines and follow new steps. Training stops mistakes and keeps your work running well. When you help your workers learn, they feel better and your business gets stronger.

| Benefit of Automation | Benefit of Training |

|---|---|

| Faster production | Fewer mistakes |

| Lower labor costs | Higher product quality |

| Consistent results | Better teamwork |

Note: A smart team and good machines help you grow without losing quality.

Marketing

Marketing helps you find new buyers and keep your business growing. Make an email list and send out news with special deals. Go to local events to show your work and meet new people. Start a referral program to thank customers who bring friends. Write blog posts and make videos to answer common questions about screen printing.

Social media is important. Use Instagram and TikTok to show pictures and videos of your prints. Plan your posts to keep people interested. Share updates, sales, and fun facts about the industry.

- Show new products or projects you are working on.

- Tell people about sales and give out discount codes.

- Share tips and facts to teach your followers.

Good marketing keeps your business seen and brings in steady orders.

You can start a profitable screen printing business by following these steps:

- Begin with low startup capital and choose fabrics like cotton or polyester.

- Prepare your design and transfer it to the screen.

- Use modern equipment, such as Cnding’s automated machines, to apply and cure the ink.

- Focus on high-demand products and customers for steady growth.

- The 80/20 rule helps you find your best customers.

- Automation and the right tools make your work faster and more reliable.

Explore more about screen printing equipment and business tips from trusted industry guides.