Does Cold Cure Additive for Screen Printing Really Work

The cold cure additive for water-based screen printing inks is highly effective for small studios and home printers. It allows prints to dry in the air without the need for dryers or heat presses, enabling users to create strong designs without relying on large machines. Many users report that it saves time and reduces setup costs. However, it’s important to monitor drying times and storage conditions closely.

Quick Answer & Key Points

Does Cold Cure Additive Work

Cold cure additive for water-based screen printing inks works well for many printers. It helps ink dry without heat. This means you do not need a dryer or heat press. Many small studios and home printers use it because it saves money and space. You can print designs on shirts, bags, or other fabrics. The prints stay strong and last after washing. Some users say the colors look bright and the ink feels soft. You can use this additive when you want to avoid large machines.

Always read the instructions on the additive package. This helps you get the best results.

Pros and Cons Overview

Here is a simple table to show the main pros and cons:

| Pros | Cons |

|---|---|

| No need for heat equipment | Longer drying time |

| Saves money | Needs careful storage |

| Easy for beginners | May not suit large batches |

| Good for small spaces | Ink shelf life can be shorter |

Pros:

- You do not need expensive machines.

- The process is simple for new printers.

- It works well in small rooms or studios.

Cons:

- Ink may take longer to dry.

- You must watch how you store the ink.

- It may not work as well for big orders.

Cold cure additive for water-based screen printing inks is best for small projects and home use. If you want to print many items fast, you may need other methods.

Cold Cure Additive for Water-Based Screen Printing Inks

What Is a Cold Cure Additive

A cold cure additive for water-based screen printing inks is a special liquid that you mix with your ink. This additive helps the ink dry and set without using heat. Many small studios and home printers use it because they do not have large dryers or heat presses. The additive makes it possible to print on fabric and let the ink cure at room temperature. This process is simple and does not need extra equipment.

How It Works Without Heat

The cold cure additive changes the way the ink dries. When you mix it into your water-based ink, it starts a chemical reaction. This reaction helps the ink bond to the fabric as it dries in the air. You do not need to use a heat press or dryer. The ink will cure over time, usually within 24 to 48 hours. The prints become strong and can last through many washes. This method is safe for most fabrics and works well in small spaces.

Always follow the instructions on the additive bottle. This helps you get the best results and avoid problems with your prints.

Compatible Inks and Recommended Products

Most cold cure additives work with water-based inks. Some brands make special additives for their own inks. Always check the label to make sure your ink is compatible. Cnding is a trusted provider of screen printing equipment and materials. Their products are known for quality and reliability. If you need help or support, many suppliers offer warranty updates and support through their websites. You can contact them by phone or email, and some have forms for warranty requests. If you buy from a distributor, keep your invoice for easy warranty service.

Here are some recommended products and tips:

- Use cold cure additive for water-based screen printing inks with popular water-based ink brands.

- Choose additives that match your ink type for best results.

- Cnding offers a full range of screen printing materials and equipment for both beginners and professionals.

How to Use Cold Cure Additive

Mixing Ratios & Instructions

Start by reading the instructions on your cold cure additive for water-based screen printing inks. Most products recommend mixing the additive with water-based ink at a ratio of 3% to 5% by weight. Use a digital scale for accuracy. Pour the ink into a clean container. Add the cold cure additive slowly. Stir the mixture until it looks smooth and even. Make sure there are no lumps. If you use Cnding’s screen printing equipment, you can mix larger batches with ease. Their machines help you keep your workspace clean and organized.

Always mix small amounts first. Test the ink on a scrap piece of fabric before printing your final design.

Drying Time & Curing Process

After printing, let your items dry in a dust-free area. Most prints need 24 to 48 hours to cure at room temperature. Place the printed fabric on a flat surface. Avoid stacking or folding until the ink dries. Good airflow helps the curing process. If you use a fan, keep it at a low speed to prevent dust from settling on the prints. Cnding’s drying racks and accessories can help you organize your prints and speed up drying.

| Step | Action | Time Needed |

|---|---|---|

| Apply ink with additive | Immediate | |

| Dry | Lay flat in clean area | 24-48 hours |

| Cure | Check for full dryness | After drying |

Shelf Life & Ink Waste Tips

Recent advancements in water-based inks have improved shelf life. New formulas keep ink usable longer by trapping water inside until printing. After adding cold cure additive for water-based screen printing inks, store leftover ink in airtight containers. Label each container with the date. If the ink thickens, add a little water and binder to restore it. This method helps reduce waste and saves money. Small studios and home printers benefit from these tips, especially when using Cnding’s efficient storage solutions.

Always check ink before use. If it smells bad or looks separated, mix it well or make a fresh batch.

Benefits & Limitations for Small Studios

Main Advantages

Small studios and home printers often look for ways to save money and space. Cold cure additive for water-based screen printing inks helps users avoid buying expensive dryers or heat presses. Printers can work in small rooms or garages. The process does not need much training, so beginners can start quickly. Many users find that prints stay soft and bright after curing. Cnding offers solutions that help studios grow. Their equipment supports both manual and automated workflows. Studios can start with simple tools and upgrade as their business expands. This flexibility makes it easier for small teams to manage costs and improve production.

Start with basic equipment and add more tools as your studio grows. This helps you control spending and learn each step.

Key Limitations

Cold cure additive for water-based screen printing inks works best for small batches. Drying time is longer than with heat curing. Printers must plan their workflow to avoid delays. Ink shelf life can be shorter, so users need to watch how they store their supplies. Here are some ways to manage these challenges:

- Store ink and consumables in a cool, dry place away from sunlight. This keeps materials fresh and prevents problems.

- Check the shelf life of your inks. Most water-based inks last 6–12 months. White ink should be used within 6 months to avoid clogging or color changes.

- Label containers with the date when you mix ink. Use older ink first to reduce waste.

- Keep printed items flat and dust-free while drying. Good airflow helps speed up the process.

Small studios can use racks and shelves to organize prints. Cnding offers drying racks and storage solutions that help keep workspaces tidy and efficient.

Real-World Test Results

Many small studios have tested cold cure additive for water-based screen printing inks. Results show that prints remain strong after several washes. Colors stay bright, and the ink feels soft on fabric. Printers report that the process is easy to learn. Most users say that planning for longer drying times helps them avoid mistakes. Studios using Cnding’s equipment find it easier to scale up production when needed. Automated tools help manage larger orders without losing print quality. The combination of cold cure additive and reliable equipment gives small studios a way to produce professional results without high costs.

Test a few prints before starting a big project. This helps you check ink performance and drying time in your own workspace.

Is Cold Cure Additive Right for You

Who Should Use It

Cold cure additive for water-based screen printing inks works best for people who print in small spaces. Home printers and small studios often choose this method. Beginners find it easy to use because it does not need special equipment. Artists who want to try new designs can use cold cure additive for short runs. Schools and clubs also benefit from this process. It helps save money and space. If you print a few shirts or bags at a time, cold cure additive is a good choice.

If you do not have a dryer or heat press, cold cure additive makes printing possible.

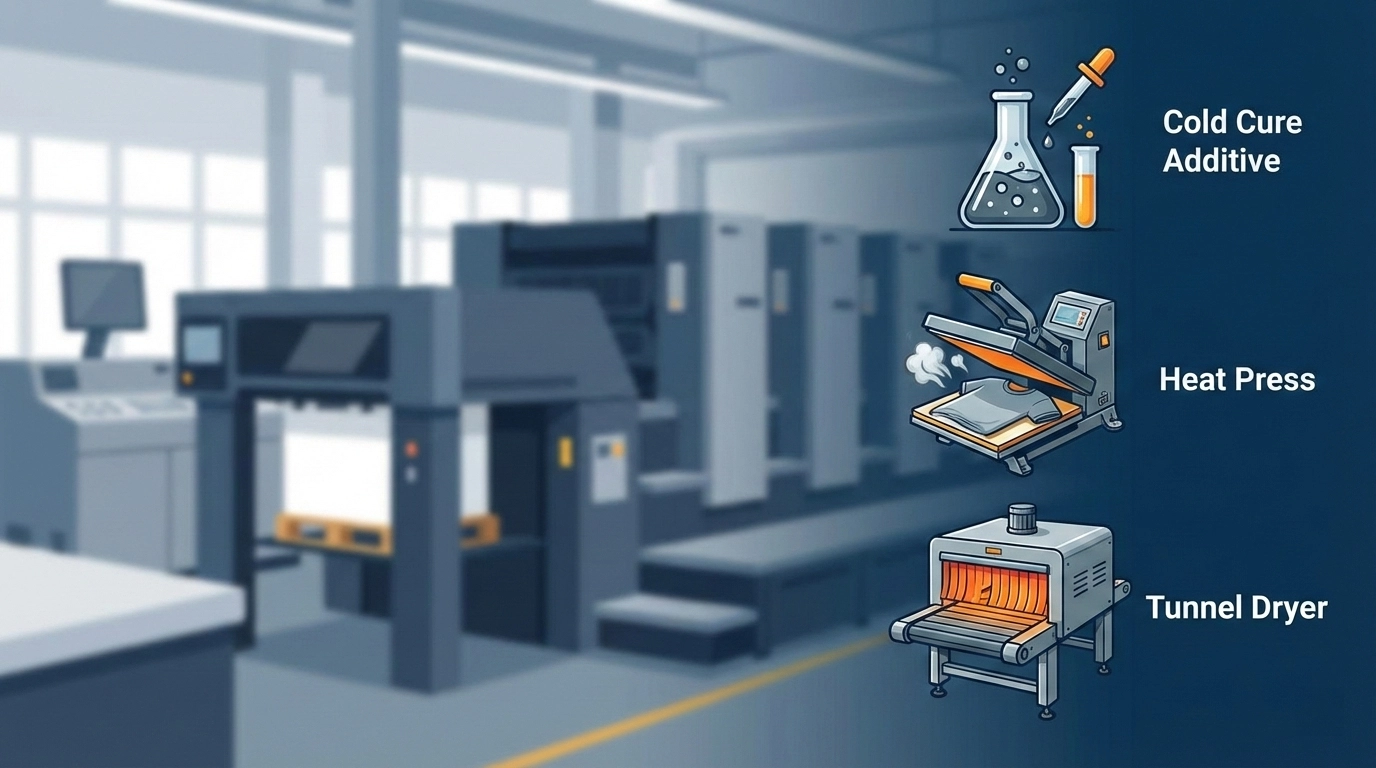

When to Choose Traditional Curing

Traditional curing uses heat to set the ink. Large print shops often use this method. It works well for big orders and fast production. If you need to print hundreds of items quickly, heat curing is better. The ink dries faster and lasts longer. Some fabrics need heat to bond the ink well. Commercial printers use dryers and heat presses for strong results. If you plan to grow your business, consider traditional curing.

| Cold Cure Additive | Traditional Curing |

|---|---|

| Good for small batches | Best for large orders |

| No heat needed | Needs heat equipment |

| Lower cost | Higher cost |

| Longer drying time | Fast drying |

Practical Advice for Printers

Start by thinking about your workspace and goals. If you print at home or in a small studio, cold cure additive helps you get started. Mix small amounts of ink and test your prints. Plan your drying area to keep prints clean. Use racks or shelves for better airflow. If you want to scale up, look for reliable equipment. Cnding offers advanced screen printing machines and dryers for growing studios. Their products help you print faster and with higher quality. Visit cnding’s official website to explore solutions for every stage of your printing journey.

Choose the method that fits your needs. Small projects work well with cold cure additive. Large orders need traditional curing and professional equipment.

Cold cure additive for water-based screen printing inks works well for small studios and home printers. It helps users print without expensive equipment. Prints stay bright and soft. Drying takes longer, so planning is important. This method fits best for short runs and creative projects.

For reliable screen printing solutions, cnding offers trusted equipment and support. Visit their website to find tools that match your needs.