What Is Mesh Fabric: Everything Beginners Should Know

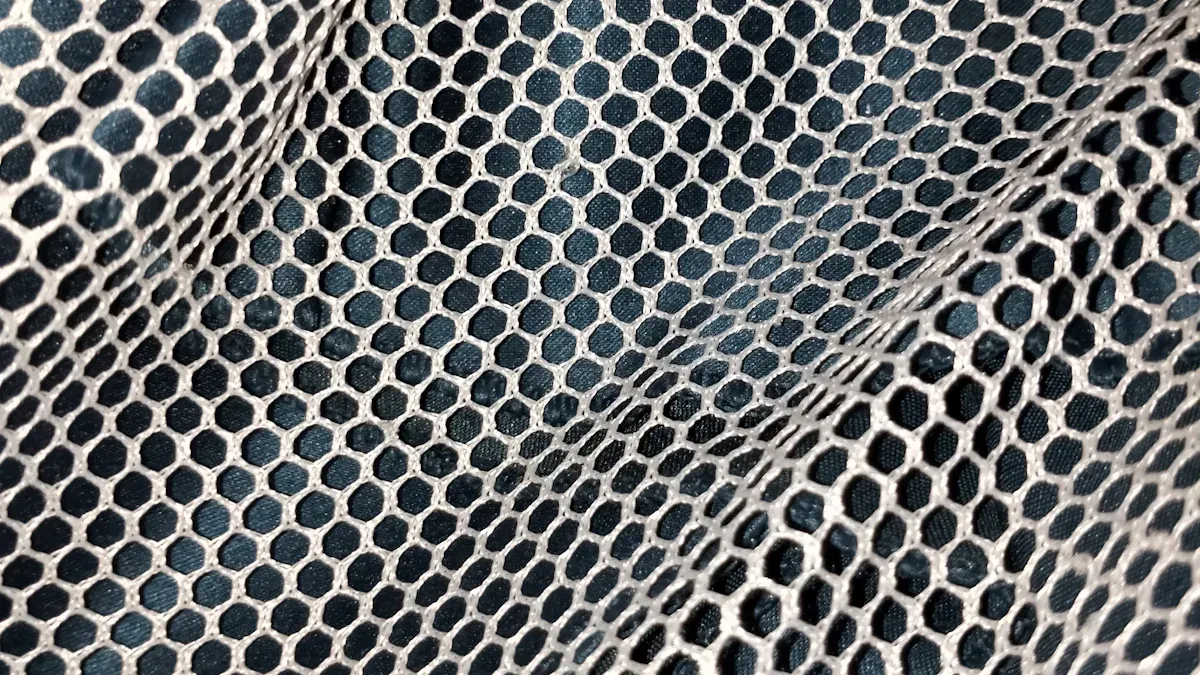

Mesh fabric features an open-weave structure that lets air and moisture pass through easily. You see this material in many products, from sportswear to industrial filters. When you touch mesh fabric, you notice its lightweight feel and see-through appearance. Many industries choose mesh material for its breathability and strength, especially in printing and textiles.

Mesh Fabric Characteristics

Structure And Appearance

You notice mesh fabric by its unique open-weave design. The structure creates small holes that let you see through the material. The size and shape of these holes can change based on how tightly the fibers are woven. Some mesh fabrics have fine holes, while others show a coarser pattern. The fiber type also affects the look and feel. You might find mesh made from polyester, nylon, or even metal. Each type gives a different finish and texture.

- Polyester mesh often looks smooth and feels soft.

- Nylon mesh can appear shiny and strong.

- Metal mesh gives a bright, reflective surface.

- The weave density changes the thickness and weight of the fabric.

- Colors and finishes vary, so you can choose mesh material that fits your needs.

Mesh material stands out because you can see the difference in weight, thickness, and color just by looking at it. The open structure makes it easy to spot in clothing, bags, and industrial products.

Breathability And Durability

Mesh fabric lets air and moisture pass through easily. You stay cool and dry when you wear mesh clothing during sports or outdoor activities. The open weave helps prevent sweat from building up. Mesh material works well in hot weather because it keeps you comfortable.

Durability depends on the fiber used. Polyester and nylon mesh resist tearing and stretching. You can wash and use them many times without losing shape. Metal mesh lasts even longer and handles rough conditions. Mesh material often appears in products that need both strength and airflow, such as sports jerseys, safety vests, and industrial filters.

Tip: Choose mesh material with a tighter weave for more durability, or a looser weave for better breathability.

Flexibility And Lightweight

Mesh fabric feels light when you hold it. You can bend and fold it without much effort. The flexible nature makes it easy to sew into different shapes and sizes. You see mesh material in shoes, hats, and backpacks because it adds comfort without extra weight.

You notice that mesh fabric moves with your body. Athletes prefer mesh clothing because it does not restrict movement. The lightweight quality also means you can pack mesh items easily for travel or storage. Mesh material helps create products that are both practical and comfortable.

Mesh Material Types

Polyester Mesh

You often find polyester mesh in sportswear and athletic gear. This mesh material stands out because it is lightweight and dries quickly. Polyester fibers resist shrinking and stretching, so your clothes keep their shape after many washes. You can wear polyester mesh for workouts or outdoor activities and stay comfortable. The fabric also wicks moisture away from your skin, which helps you stay dry. Many brands choose polyester mesh for team jerseys, hats, and even bags.

- Lightweight and breathable

- Quick-drying and moisture-wicking

- Keeps its shape after washing

Nylon Mesh

Nylon mesh is another popular choice in the textile industry. You see it in everything from beekeeping veils to medical gear. Nylon mesh offers high tensile strength and resists tearing or stretching. You can use it in tough environments because it stands up to moisture, chemicals, and even UV rays. This mesh material also bends easily, so you can shape it for different uses. Nylon mesh comes in many colors and patterns, making it easy to match your needs.

- Strong and flexible

- Resistant to moisture, chemicals, and sunlight

- Customizable in size, color, and weave

Tip: Choose nylon mesh for projects that need both strength and flexibility.

Cotton Mesh

Cotton mesh feels soft and natural against your skin. You often see it in polo shirts, casual wear, and some sports clothing. Cotton mesh lets your skin breathe, which keeps you cool on warm days. It absorbs moisture well, though it may take longer to dry than synthetic options. Many people like cotton mesh for its comfort and classic look.

- Soft and comfortable

- Breathable and absorbent

- Common in everyday clothing

How Mesh Fabric Is Made

Materials Used

You find that mesh fabric starts with strong and reliable raw materials. Polyester stands out as the most common choice because it offers durability and high quality. Other materials like nylon and cotton also play a role, depending on the final use of the mesh. Each material brings its own strengths, such as flexibility, softness, or resistance to wear.

| Raw Material | Description |

|---|---|

| Polyester | The primary raw material used in the production of mesh fabric, known for its superior quality and durability. |

| Nylon | Adds flexibility and strength, often used for technical or industrial mesh. |

| Cotton | Provides softness and breathability, popular in casual and sports clothing. |

You select the right mesh material based on the product’s needs. For example, you might choose polyester for sportswear or nylon for industrial filters.

Manufacturing Techniques

The process of making mesh fabric involves several important steps. You begin by sourcing the raw materials, then spin them into yarn. Next, you weave or knit the yarn to create the open structure that defines mesh. Some mesh fabrics use weaving for a firm, stable pattern. Others use knitting for extra stretch and flexibility. After forming the mesh, you finish the fabric with treatments that improve texture, color, or durability.

| Step | Description |

|---|---|

| Harvesting Process | Involves sourcing raw materials like polyester, nylon, or cotton from large-scale processes. |

| Spinning | Raw fibers are twisted together to create long strands of yarn. |

| Weaving | Yarn is woven to form the mesh pattern, creating an open structure for airflow. |

| Knitting | Some mesh fabrics are knitted for flexibility, using loops of yarn. |

| Finishing | Fabric is treated for texture, durability, or appearance, including dyeing and coatings. |

| Quality Control | Ensures consistency in weave, strength, breathability, and color retention of the final product. |

Cnding’s advanced screen printing automation equipment supports these manufacturing steps. You benefit from precise control, high efficiency, and consistent quality. Cnding’s machines help you produce mesh fabric with fewer defects and faster turnaround.

Comparison With Other Fabrics

When you compare mesh fabric to other textiles, you notice key differences. Mesh stands out for its open structure, which allows air and moisture to pass through. Traditional woven or knit fabrics often feel heavier and less breathable. Mesh material gives you a lightweight, flexible option that works well in sportswear, industrial uses, and printing. With cnding’s technology, you achieve high-quality mesh fabric that meets modern demands for comfort and performance.

Note: Mesh fabric’s unique structure and production process make it a top choice for many industries, especially when you need breathability and strength.

Care And Sustainability

Cleaning And Maintenance

You can extend the life of mesh fabric with simple care routines. Follow these steps to keep your mesh items looking and performing their best:

- Dust Regularly: Use a microfiber cloth or a vacuum brush attachment to remove dust each week.

- Spot Clean with Mild Soap: For stubborn stains, gently dab the area with a damp cloth and mild soap. Avoid harsh chemicals.

- Avoid Waterlogging: Do not soak mesh fabric. Lightly dab dirty spots to help the material keep its shape.

- Keep Mesh Dry: Make sure items like mosquito nets stay dry to prevent mold and weakening.

- Clean Gently: Use a handheld vacuum or soft brush for regular cleaning. Wipe with warm water and mild detergent if the mesh gets greasy.

- Inspect for Damage: Check for tears or loose edges and repair them quickly.

Cnding offers training and support to help you care for mesh fabrics used in screen printing. Their after-sales service ensures you use the right cleaning methods for your equipment and materials.

Cost Factors

Several factors influence the cost of mesh fabric in the market. You can see the main drivers in the table below:

| Factor Type | Description |

|---|---|

| Market Segmentation | Divides the market by product type, end-user, and region. |

| Industry Drivers | Includes trends and demands that boost mesh fabric use. |

| Market Challenges | Covers issues that may slow market growth. |

| Competitive Landscape | Looks at key companies and their strategies. |

| Economic Environment | Considers economic trends that affect prices. |

| Technological Environment | Focuses on new technology that changes how mesh fabric is made. |

Cnding’s advanced automation equipment helps you lower production costs by reducing waste and increasing efficiency. Their machines let you produce high-quality mesh fabric at a competitive price.

Environmental Impact

Mesh fabric production, especially from cotton, uses a lot of energy and water. Cotton farming can have a big climate impact, with emissions ranging from 0.5 to 6 kg of CO2 for every kilogram of fiber. Energy use in cotton production varies, sometimes reaching up to 90 megajoules per kilogram. Most textile factories rely on fossil fuels, which increases the environmental footprint. Cnding’s technology helps you reduce waste and energy use by making production more efficient. You can choose equipment that supports sustainability goals and helps protect the environment.

You now understand mesh fabric’s open structure, breathability, and flexibility. You can choose from polyester, nylon, cotton, or specialty mesh for clothing, industry, or home use. Quality mesh and reliable equipment, like those from cnding, help you achieve better results and efficiency.

- Explore mesh fabric for your next project.

- Consider expert solutions for smooth production.

Have questions about mesh fabric or printing equipment? Reach out for more information and guidance.